Complete PVC pelletizing plant

Year of installation:

2018/2019

Condition:

very good running condition

Output rate:

up to 400 kg/h for PVC

Description:

Complete PVC pelletizing plant

Capacity: 300 - 400 kg/h (depending on material composition)

Description:

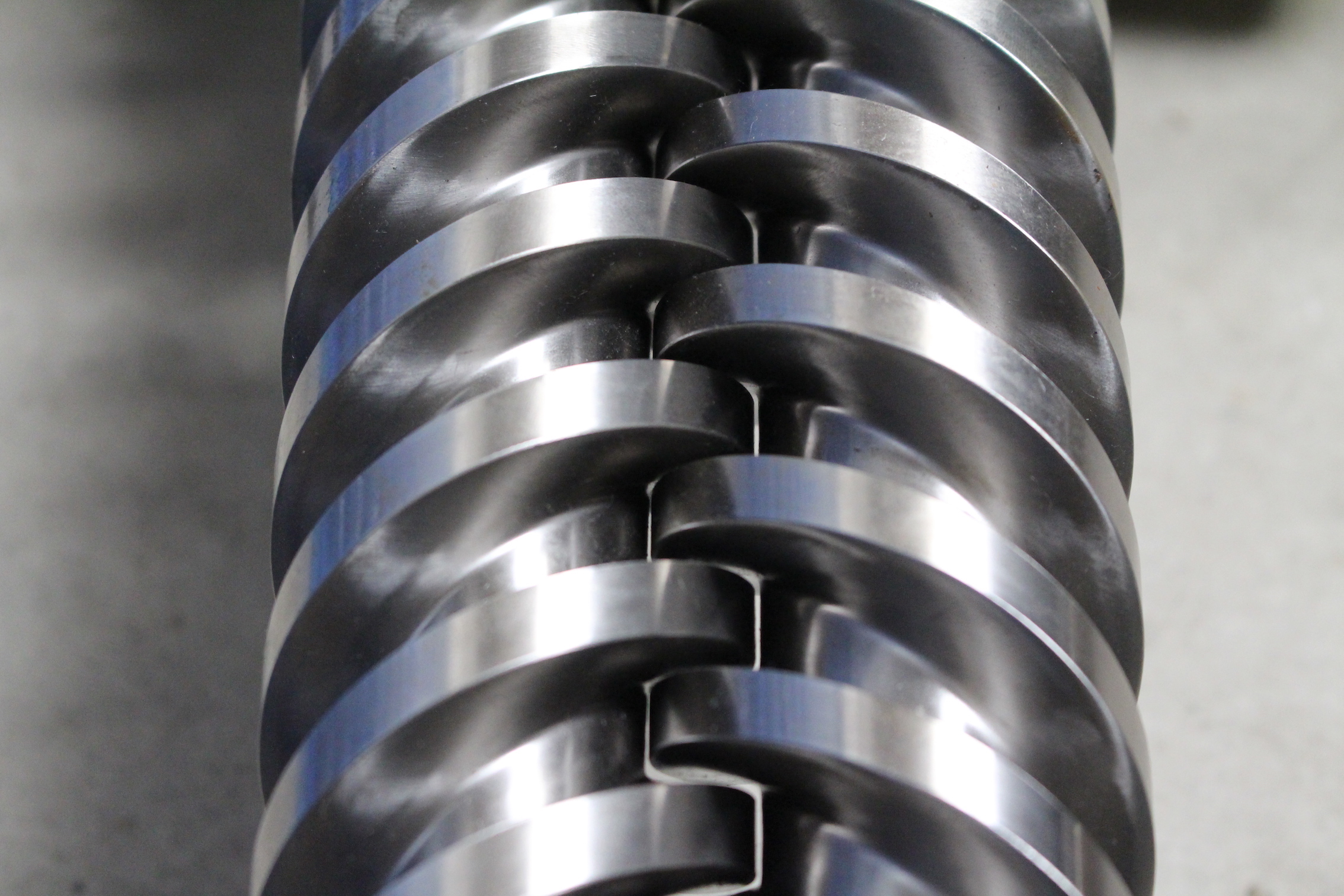

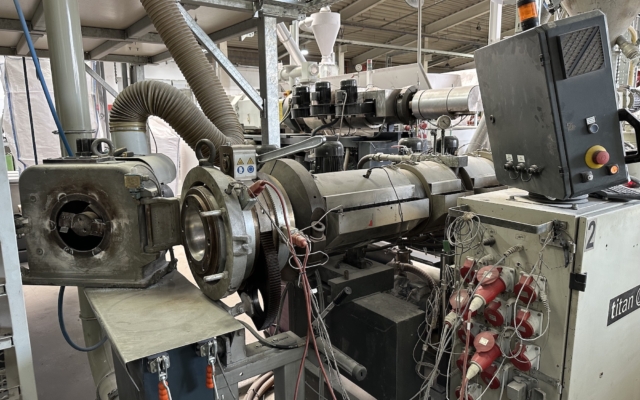

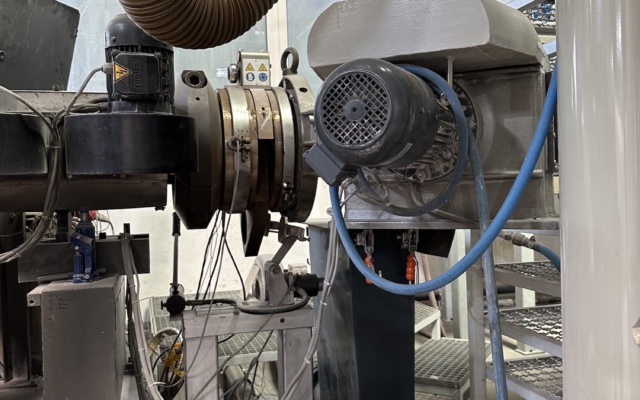

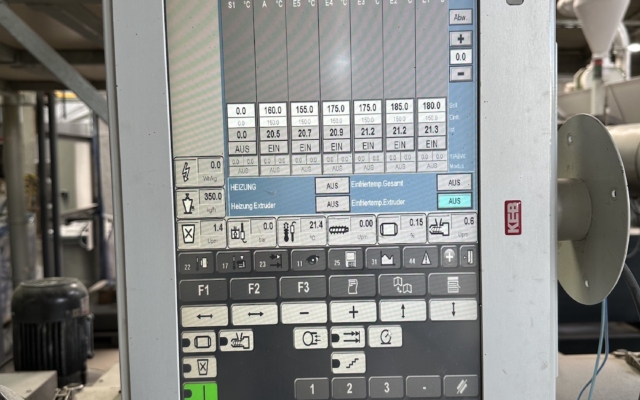

Conical Twin-Screw Extruder Cincinnati type: Titan92-APC

Year of manufacture: 1996

incl. volumetric dosing unit for masterbatch: Wittmann Dosimax

Manual Screen Changer type: BD Plast

Installed between extruder adapter and pelletizing head

Alternative:

Genuss screen changer

Pelletizing Head Cincinnati type: GK120

Operates using the hot-cut method incl. adapter and discharge chute

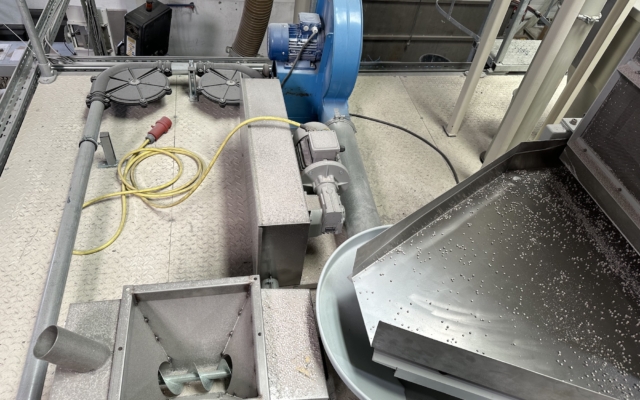

Circular Vibrating Screen IFE type: US 400 x 1000 FV – LM445T

Year of manufacture: 2018

for separating particles not bound in the granulate with particle size < 1.8 mm

Vertical Pellet Cooler Knorr type: GK-600-PVC

Year of manufacture: 2018

Cooling volume: approx. 190 liters

Mounted on a walkable steel platform, incl. cyclone separator,

complete inlet and outlet piping and blower

Big Bag Filling Station

incl. material transport and material weighing system: SBB weighing technology

Condition:

fully functional

Can be inspected in operation